Pro Tips for Maintaining Your Commercial Roll-Up Garage Door

Last winter, a large warehouse in Texas City called us in a panic. Their insulated roll-up garage door was stuck halfway open during a sudden cold snap. Deliveries were delayed, valuable warm air was escaping, and their energy bills were rising fast. When our team arrived, we discovered the issue stemmed from neglected rollers and a severely worn urethane weather seal, two components that often go unnoticed during routine operations. Had there been regular maintenance checks in place, the malfunction could have been prevented entirely.

Did you know? A well-maintained commercial insulated garage door can reduce energy loss by up to 40%, according to leading facility management studies. That’s not just a cost-saving figure it represents improved operational reliability, extended equipment lifespan, and a more sustainable footprint for your business.

At Mainland Garage Door Center, we’re proud to serve Texas City, TX, with expert maintenance and installation of commercial roll-up garage doors. We use high-grade materials like galvanized steel, polyurethane cores, polystyrene panels, and weather-rated urethane seals to ensure lasting durability. Let’s break down our top expert tips for keeping your doors performing like new year-round.

Why Maintenance Matters for Commercial Garage Doors

Your commercial roll-up door does much more than allow trucks in and out it serves as a thermal shield, security checkpoint, and environmental barrier. Especially in warehouses, distribution centers, auto shops, or manufacturing plants, the garage door plays a vital role in maintaining efficiency and safety.

Key Benefits of Regular Maintenance:

- Extends Lifespan: Reduces wear on moving parts like torsion springs, rollers, tracks, and bearings.

- Preserves Insulation: Maintains high R-values and U-values for thermal regulation.

- Enhances Energy Efficiency: Prevents heat loss in winter and keeps cool air in during summer.

- Reduces Downtime: Minimizes emergency repairs and service disruptions.

- Improves Safety: Prevents accidents by ensuring sensors, cables, and openers function properly.

1. Inspect All Door Components Regularly

A comprehensive monthly inspection is your first defense against breakdowns.

What to Check:

- Door Panels: Look for rust, dents, or warping, especially in steel or aluminum surfaces.

- Tracks and Rollers: Worn or misaligned tracks cause uneven operation and put stress on the opener.

- Springs: Torsion springs should show no signs of fraying, rust, or imbalance.

- Insulation Cores: Check polyurethane or polystyrene panel cores for cracks, moisture penetration, or compression.

- Hardware: Bolts, hinges, and brackets should be tight and free from corrosion.

Pro Tip: Use a flashlight to inspect behind and underneath components; some signs of wear are not visible during basic operation.

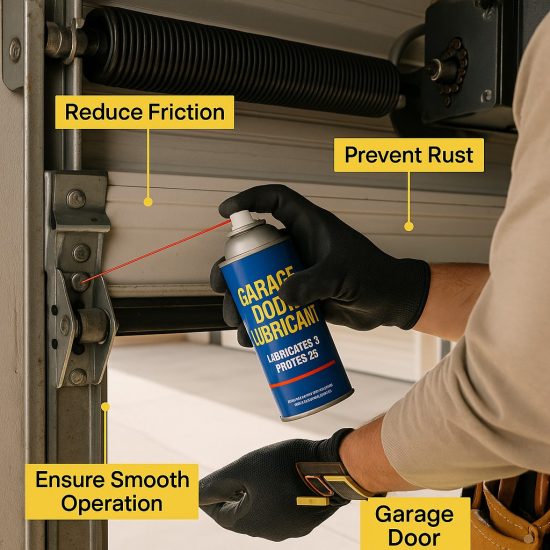

2. Clean and Lubricate Moving Parts

Debris and lack of lubrication are among the top causes of premature wear on garage door systems.

Maintenance Routine:

- Clean Tracks: Use a degreasing cleaner to remove grit and dust from the tracks.

- Lubricate Components: Apply garage-specific lubricant to hinges, torsion springs, bearings, and rollers.

- Avoid WD-40: It’s a solvent that strips lubrication. Instead, opt for lithium-based or silicone garage door lubricants.

- Remove Debris: Wipe down surfaces to prevent buildup that affects performance.

A lubricated system ensures quieter operation, less wear on the opener’s motor, and increased lifespan of key parts.

3. Don’t Ignore the Insulation

Insulation in commercial garage doors isn’t just for comfort; it affects energy bills, product storage conditions, and employee working environments.

Insulation Checkpoints:

- Foam Cores: Look for cracks or compression in rigid foam, especially in extreme climates.

- Weather Seals: Inspect the bottom seal, side weather stripping, and urethane barriers for signs of drying, cracking, or detachment.

- Condensation: Moisture inside panels may indicate failing vapor barriers or damaged insulation kits.

Even heavy-duty materials like polyurethane foam or batt insulation can degrade over time, especially with exposure to chemicals, temperature extremes, or UV light.

4. Balance and Test the Door

An unbalanced garage door places excessive strain on the motor, springs, and logic board of your opener.

How to Test:

- Disconnect the Opener: Use the emergency release handle.

- Lift the Door Manually: Raise it to the halfway point.

- Watch for Movement: If it stays in place, your door is balanced. If it shifts, a spring adjustment is needed.

Don’t Forget:

- Sensor Alignment: Misaligned or dirty photo-eye sensors may cause false stops or fail to reverse on contact.

- Spring Tension: Always leave spring tension adjustments to professionals—they are under high pressure and can be dangerous.

5. Reinforce Weather Protection

Doors in Texas City face unique challenges: salt air from the coast, high humidity, scorching summers, and unexpected storms.

Key Areas to Reinforce:

- Bottom Seals: Replace compressed seals to maintain a thermal and pest barrier.

- Side and Top Strips: Ensure seals are intact to block drafts and moisture.

- Rust Protection: Use powder-coated or galvanized steel panels that resist corrosion.

- Thermal Barriers: Consider upgrading to doors with energy-efficient materials like Styrofoam-backed panels or polyurethane-insulated steel for climate control.

6. Check and Upgrade the Opener

Technology has advanced significantly in the last decade. Modern commercial door openers offer safety, security, and energy savings far beyond their predecessors.

Signs You Need an Upgrade:

- Slow or noisy operation

- Inconsistent remote control response

- No Wi-Fi or smart integration

- Frequent opener board malfunctions

Upgrade Benefits:

- Smartphone Control: Manage door access remotely.

- Energy-Saving Modes: Newer models draw less power on standby.

- Enhanced Safety Logic Boards: Prevent injuries and comply with OSHA standards.

Brands like Chamberlain, Craftsman, Clopay, and Martin Garage Doors offer high-performance options for commercial-grade reliability.

7. Train Staff to Operate Doors Safely

A well-maintained door can still fail if mishandled. Make door safety a part of employee training.

Training Tips:

- Proper Use: Teach employees to open and close the door slowly and without force.

- Watch for Signs: Unusual grinding sounds or delayed movements should be reported immediately.

- Area Clearance: Keep the space around the door clear of storage items or carts.

- Lockout Procedures: Ensure staff know how to engage/disengage the opener in case of power failure.

A few minutes of training can prevent thousands in repair costs and ensure OSHA compliance.

8. Schedule Seasonal Tune-Ups

The best way to avoid costly repairs is through seasonal preventive maintenance. Think of it as a check-up for your door system.

Mainland Garage Door Center Tune-Up Checklist:

- Full inspection of tracks, rollers, brackets, and fasteners

- Spring tension adjustment and lubrication

- Garage door opener diagnostic and logic board check

- Cleaning and inspection of insulation layers and vapor barriers

- R-value performance testing and weather seal evaluation

Whether your building uses non-insulated sheet doors or insulated sectional doors, our team can optimize them for energy savings, smoother operation, and compliance with local building codes.

How Can Mainland Garage Door Center Help You?

We’re proud to be Texas City’s trusted partner for all commercial garage door services, from installation and upgrades to maintenance and emergency repairs.

📍 Visit Us: 10000 Emmett F Lowry Expy Avenue 9, Texas City, TX 77591

📞 Call Now: (832) 536-6690

Whether your facility uses roll-up doors, sectional doors, or legacy garage systems, we work with top-rated brands and offer custom-fit solutions. From retrofitting with insulated panels to installing Wi-Fi-enabled smart openers, we’ll help you find the best options for your needs and budget.

Ask us about our seasonal maintenance packages, they’re the easiest way to protect your investment and keep your operations running smoothly.

Frequently Asked Questions (FAQs)

1. How often should a commercial roll-up garage door be serviced by a professional?

At least twice a year, ideally in spring and fall. This catches early wear, keeps insulation effective, and reduces unexpected breakdowns.

2. Can I add insulation to an existing commercial garage door?

Absolutely. Retrofit insulation kits, such as reflective foil panels or rigid foam inserts, can be custom-fitted to existing doors for enhanced energy performance.

3. What is the average lifespan of a commercial roll-up garage door?

With proper care and professional maintenance, most commercial doors last 15 to 30 years, depending on usage, environment, and material quality.

4. Are insulated commercial garage doors quieter than non-insulated ones?

Yes. Insulated panels dampen sound, making them ideal for urban environments, high-traffic zones, or buildings with noise-sensitive operations.